In-house tool design & full material traceability

10mm - 125mm

CAPABILITIES

Solving manufacturing requirements of the most technically demanding parts. With decades of experience, we are the only specialist you need for precision turned components made from brass & more.

Cost-effective solutions with the latest multi-spindle screw machining capabilities

TELEPHONE:

+44(0)121 236 8986

EMAIL:

sales@curriewarner.com

Just in time

turned parts manufacturing

Whether you’re in the automotive sector or heating, ventilation and air-conditioning, our call off facilities help our customers manage their budget and floor space.

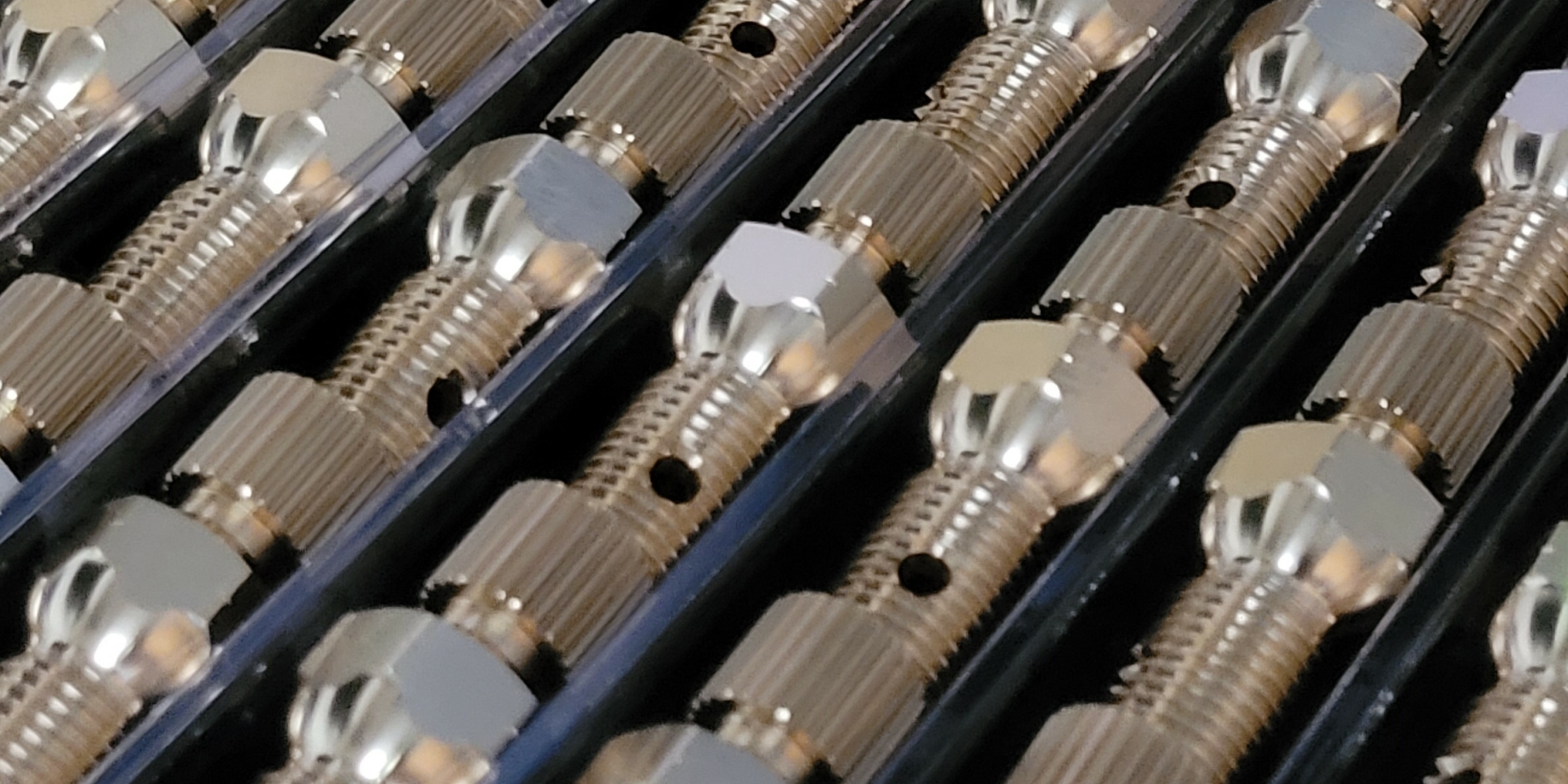

Brass Bespoke

Parts Manufacturer

We manufacture a wide variety of turned parts and brass machined components to an exacting standard. Below are just some of the components we produce at our Birmingham facility:

“Cannot recommend Currie & Warner enough. Their expertise helped our company secure multiple business opportunities. They helped us improve on the quality and efficiency of our product and now we’re the number 1 distributor across the UK in our sector”

Andy Smith

Managing Direction / Plumbsite Solutions UK Ltd

“I’ve used multiple companies for my ECOBRASS components, but no one comes close to the quality that Currie & Warner provide.”

Mark Jones

Engineer / UK-Brass fabrications

High performance ECO BRASS components manufactured to your specification

We’ve been working with EcoBrass for over 15 years, a lead free material with superior strength, exceptional wear & corrosion resistance.