Inspection

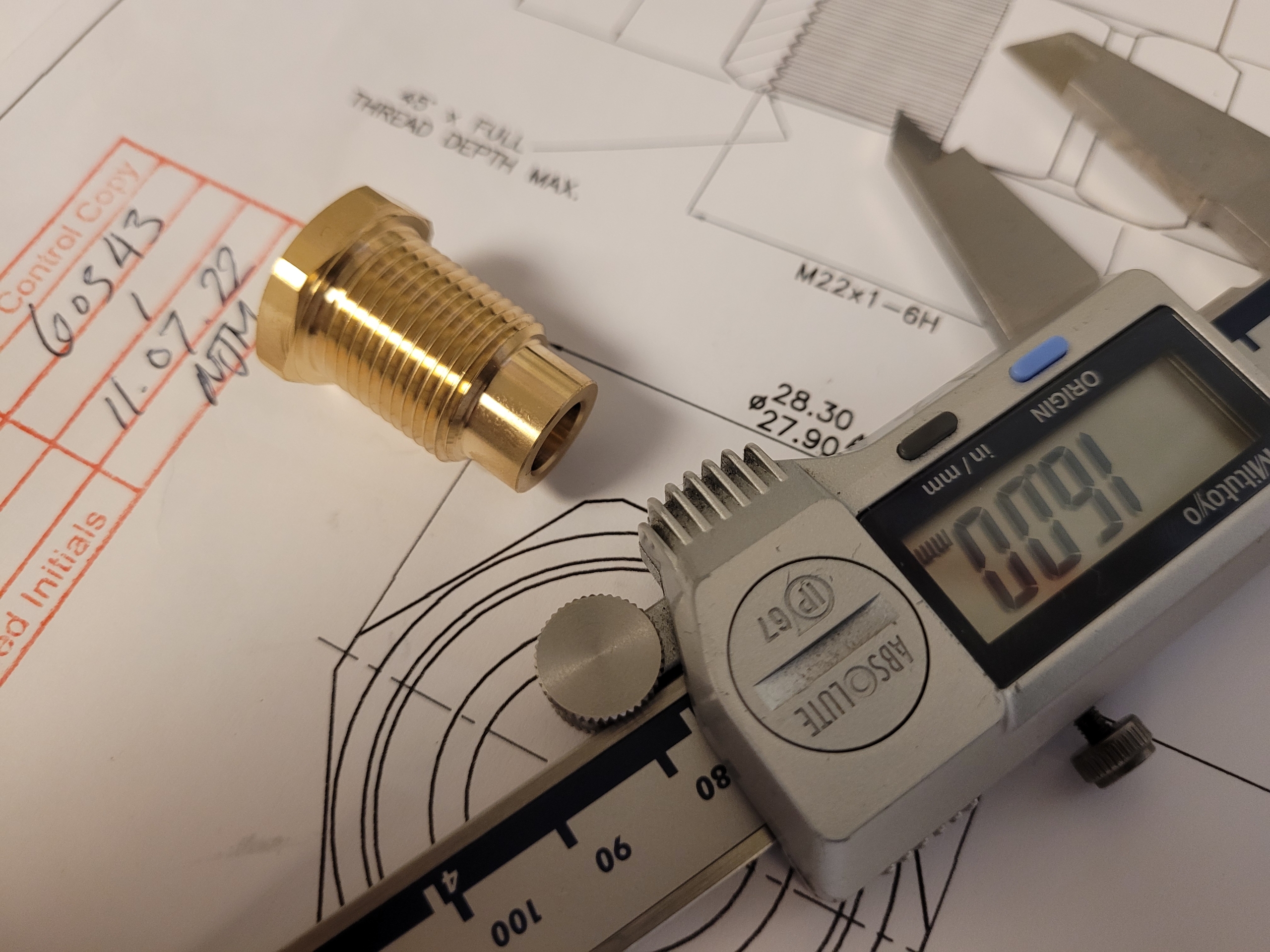

Quality Assurance is a key aspect of our business. At the inspection stage, we use the Acceptable Quality Limit (AQL) procedure to sample check production batches and ensure they comply with the customers' specifications.

The quality plan controls all aspects of the inspection process including tolerance, measurement method, measurement frequency, etc. Generally, the equipment used for AQL inspection is as follows:

- Coordinate Measuring Machine

- Direct Measuring Equipment

- Attribute Gauges

- Special Purpose Gauges

- Automated Sorting Machines

- 100% Optical Sorting Machine

Our aim is to provide zero defects, so we use AQL sampling plans but if a defect is found a larger sample batch will be checked and if a further defect is found the batch of product is usually 100% sorted.

TELEPHONE:

+44(0)121 236 8986

EMAIL:

sales@curriewarner.com