High Volume Brass Turned Parts

High volume brass turned parts are where Currie & Warner excels. We have two efficient manufacturing facilities which are geared for high-precision, high-volume production batches.

Bulk Purchasing

Currie & Warner's experienced and competent buyers constantly monitor commodity markets, analysing price fluctuations and capitalising on the best time to place material contracts. We then work closely with our customers to ensure they are getting the most competitive price when placing orders. Thus giving our customers confidence we have their business interests at heart.

Bulk Packaging

When designing packaging we take the design of material handling equipment into consideration. This enables us to rapidly package multiple components, reducing packaging time and costs. The packaging also protects the components during transit. Packaging is designed to be reusable ensuring our environmental impact is minimal.

Volume Storage

Currie & Warner tries to manufacture annual requirements in one production batch to maximise efficiencies and reduce costs for our customers. However, our customers don't always want their annual requirement in one delivery. The advantage of using Currie & Warner is, that we hold stock for up to 12 months. We deliver on a monthly or weekly schedule and customers are able to call off a product as and when required, or pull forward schedules if demand increases.

Dedicated Swarf Handling

To process the vast amount of by-products generated, we have two large swarf handling plants. They filter the swarf into manageable chippings and segregate cutting fluid. The cutting fluid is piped back to our machines, whilst the dry swarf is stored in large silos. When raw materials are delivered the same vehicle collects the swarf and returns it to the brass mill to recycle it back into rod form making the process very environmentally friendly.

Batch Inspection

Currie & Warner use a variety of methods to control quality for high volume production, from Special Process Control (SPC) to Average Quality Level (AQL) batch checking. We design and build special purpose equipment to efficiently 100% check features.

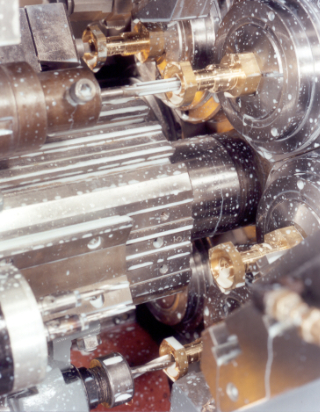

Production Machines

In excess of 50 Multi-Spindle Wickman machines with an average cycle time of 6 secs per component. Using tooling techniques developed over many years ensures quality is reliable and repeatable over large batch production.

Solvent Cleaning Plant

With the ability to process more than 1,000 pcs per minute our cleaning plant removes swarf particles, oil contaminants, and coolant residue. Often parts are packed directly after the cleaning operation.

TELEPHONE:

+44(0)121 236 8986

EMAIL:

sales@curriewarner.com